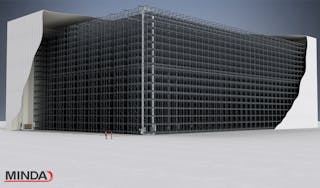

High-bay warehouse (HBW)

The High-Bay Storage in silo design, in which the high-bay rack presents the supporting substructure for the roof and the front, provides safe storage up to a height of 40 m.

The entire area is optimally utilized and yet there is fast and secure access to the goods. Warehouse optimization processes can be carried out during quiet stock removal times, for example at night. The compilation of order-related goods from the High Rack Storage and the provision of the goods for truck transport are possible.

Application:

- In the field of order picking

- In the finished goods sector

- Need for high storage capacity

Finished goods warehouse in silo design

High-bay warehouses are especially efficient automated storage systems in a compact design allowing an optimal space utilization and having a high storage density at the same time.

You have direct access to the corrugated board stacks with a high process speed and reliability.

MINDA adapts the number of stack positions to your individual needs. There are hardly any limits concerning the layout, the number of aisles, the structure of the warehouse and the number of stack positions.

For maximum efficiency, extensive analyses of your product portfolio provide us with information on the optimum compartment layout, the design of the compartments and the storage depth, which will be taken into account for the layout of your warehouse. This clustering implies both the dimensions of loads as well as the distribution of the weights.

If there are limitations in height, for example due to restrictions of monument protection or similar, the finished goods warehouse can also be built in an in-house design.

Storage and retrieval machine

Load-handling equipment

MINDA relies on the experience of well-known manufacturers as far as storage and retrieval machines are concerned. The big advantage for our customers is that they get the ideal equipment for their projects instead of equipment that fits best into the manufacturer's standard.

Depending on the project requirements, we either use storage and retrieval machines with telescopic or satellite technology as load handling equipment. This option allows the modular storage of large and small formats for an optimum storage utilization. A combination of both technologies can also be implemented. However, the dependence on the number of stack positions to capacity must always be taken into account.

Advantages of telescopic technology:

- Type of storage: single deep, double deep, triple deep

- After inspection of the application, a quadruple deep storage could also be rendered possible

- Load transport up to 4.5 t possible, higher loads only after inspection

- Small frame size despite low deflection

Advantages of satellite technology:

- Type of storage: multi-deep

- Transport of loads up to 1.5 t possible

- Powerful, wireless energy storage system with minimum reloading time

- Wireless communication

- Low lifting with short lifting times

Labelling robot - EMIL

For machine operators’ relief, we offer you the possibility to attach pallet slips to your finished goods with the help of a robot. This can be done after palletizing, either in front of or behind the strapping / wrapping machines.

The MINDA MoveIT tracks the data of the blocks (labelling position, glue pattern and label) and then the pallet slips are printed.

The robot sucks the pallet slip, crosses a spray needle and afterwards the packing slip is glued at the required customer position. Each pallet can be tagged repeatedly with the same or different labels. Here it is possible to label both wrapped and normal cardboard stacks. The use of a special glue ensures that the label is removable completely and undamaged, even from printed cardboard boxes. For an ideal gluing result you can choose from several glue patterns and determine them individually for each product.

Advantages:

- Fully automatic labelling

- Individual and reproducible label position

- Precise label positioning

- High process reliability

- Removable undamaged labels

- No glue residues

- Suitable for the food industry

The MINDA labelling robot EMIL marks goods at almost any position. A special hot glue ensures that the labels can be removed without damage even after a long time. The high positioning accuracy of the labels ensures a good detection in automatic systems.

Plastic chain conveyor for the high-bay warehouse

Advantages:

- Flexible working widths and lengths adjusted to every warehouse

- Can be equipped with fire protection flaps

- Smooth transport through frequency-controlled drives

- Reverse operation mode

- Low maintenance expenses

- High safety for the operating personnel

- Order-related composition possible

- Complete visualization and material flow tracking in the HBW

Further MINDA solutions for the corrugated board industry.

Our services and fields:

Our services and fields: