Manrider System

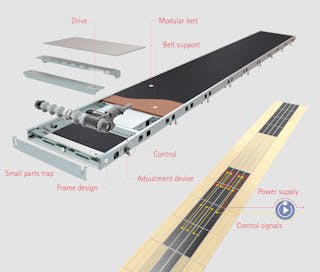

Our manrider system with modular people-mover conveyors offers adaptable layouts with very low overall heights of just 120 mm.

More ergonomic and efficient people movers

Our people-mover conveyors are vital in the automotive sector because they allow assembly workers to move with the vehicle. This is less tiring because workers can stand while working and don’t need to walk alongside the moving vehicle body.

The modular people-mover conveyor offers a stable and safe platform and ensures that there’s a distance, important for health and safety reasons, between the vehicle body and the area where materials are deposited. Our special drive technology ensures exact synchronicity of the modular people-mover conveyors and therefore maximum productivity when assembling vehicles.

Have a look at the detailed features in our interactive web animation:

Ultra-flat and adjustable

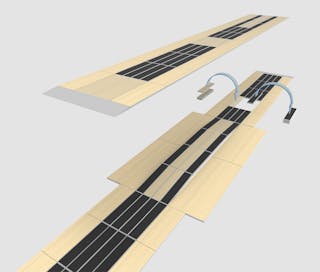

The people-mover conveyors integrate perfectly with the most diverse of production environments and can be synchronised with existing electric monorail systems (EMSs) or skid conveyors.

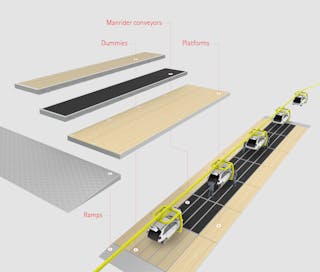

A series of our modular conveyors can be connected with each other or operated as stand-alone options. Within a very short time, they can be installed at any location and moved based on our plug and play principle. People-mover conveyors, platforms and ramps can produce cost-effective, modifiable assembly levels with low overall heights of just 120 mm and without any foundations.

The conveyors consist of plastic modular belts, which enable easy maintenance and exchange of worn-out or damaged components.

Flexibility for tomorrow and way into the future

In contrast to continuous conveyors, which are inflexible and require huge investment, our modular, people-mover conveyors adapt to the production cycle concerned. People-mover conveyors are replaced with dummies when no conveying is currently needed.

Should manufacturing process requirements change, for example if a model is replaced, the belts are easy to move and there’s no longer any need to take pits and long conveyors into account.

Further MINDA solutions for the vehicle sector

Our services and fields:

Our services and fields: