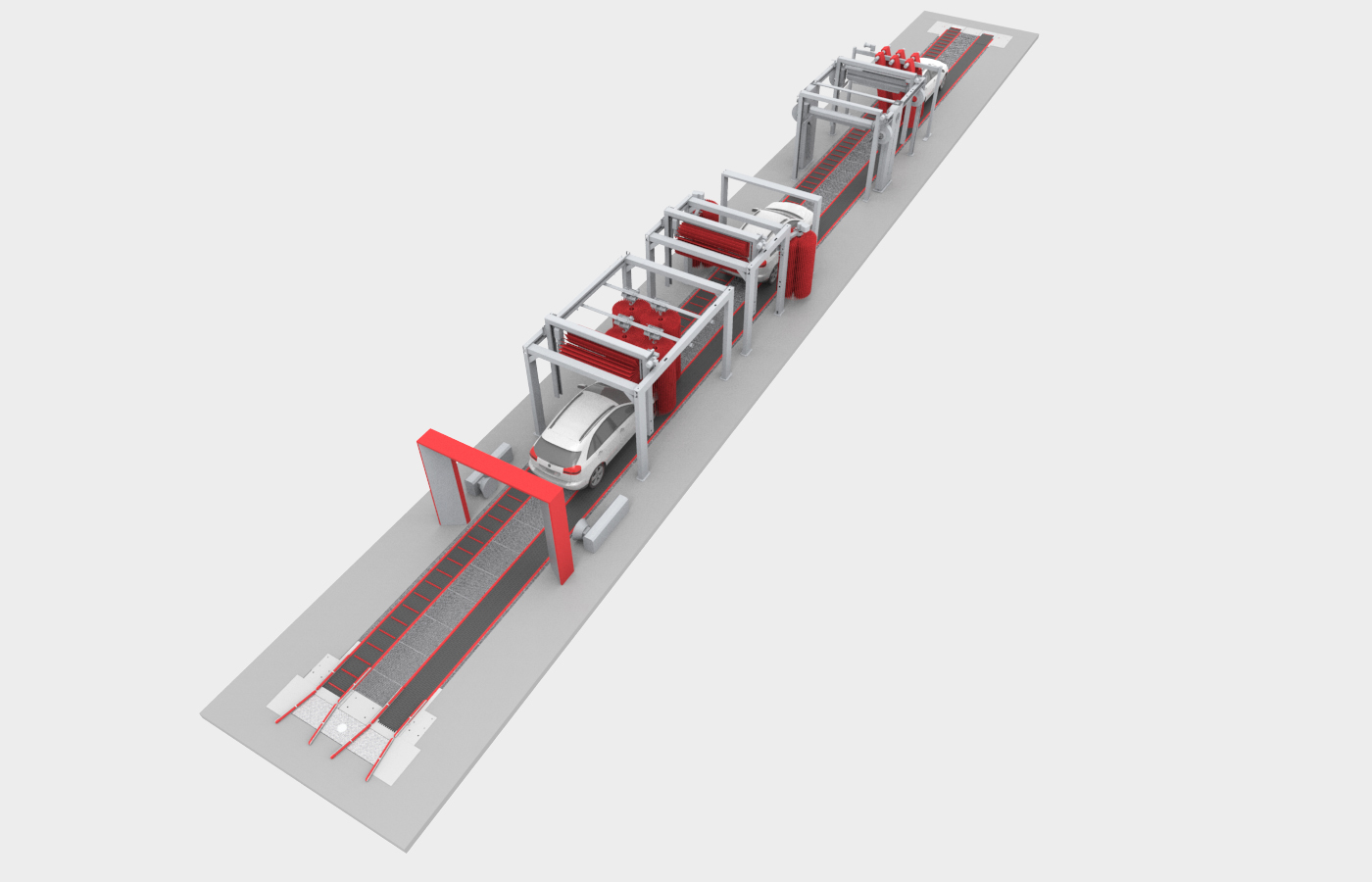

Double-track conveyor system

The double-track conveyor systems belong to the safest and most efficient solutions for the transport of private cars through modern car washes. Due to our long-term experiences our conveyor systems have been developed to a flexible and modular system. This allows simple and fast installation while simultaneously the system is variable, robust and maintenance-friendly. With a high lifetime and user-friendly handling, our conveyor system provides an efficient and reliable solution for your car wash.

The guide rollers position the vehicle precisely and safely on the conveyor system.

- Robust rollers and guiding elements made of high-quality plastic

- Stainless steel profiles ensure durability and high stability

- Available...

The shifting plate in combination with the guide rollers, aligns the vehicle when it enters the conveyor system and positions it correctly.

- Low profile height of 200 mm

- Variable width

- High-quality construction made of...

The side guide rollers provide additional vehicle alignment behind the guide rollers and ensure precise positioning on the conveyor system, especially in narrow or curved entry areas.

- Robust rollers and guiding elements...

The modular belt is made of high-quality plastic and connecting bolts made of stainless steel. They are tailor-made according to individual operating conditions.

- Easy to install

- Individual links can be replaced

- No special...

The car pusher has a decisive role for safe transportation.

- Individually tailored to specific requirements

- Available in various colors

Data sheet with detailed drawing (PDF)

Learn moreThe drive station convinces by a maintenance-friendly design and a high-performance dual-gear motor concept.

- Two gear motors ensure operation in case of a motor failure

- Floor-level construction – ideal for vehicles with...

Covers – our high-quality standard for the conveyor system.

- In the entry and exit area: Cover plates made of hot-dip galvanized steel, providing safe and easy access to the maintenance areas underneath

- In the area of the...

Together with our customers, we plan customized pits for their conveyor systems, considering local conditions.

- Creation of digital 2D and 3D pit layouts

- Long-term experience in cooperation with different property...

The modular belt sections convince by high-quality materials and a sophisticated design.

- Fast and easy installation

- Plastic side guide rail available in various colors

- Slide plates made of 6 mm stainless steel

- Galvanic...

The spray bar, optionally mounted at the deflection station, cleans the plastic chain before it enters the system by directed water application.

- Prevents damage caused by coarse dirt particles

- Reduces wear on the chain and...

The deflection convinces by maintenance-friendly design and the use of high-quality materials.

- Central lubrication point for all bearings

- High-quality construction made of hot-dip galvanized steel

- Robust sprockets made of...

Digital spare parts catalog tailored to your conveyor system.

- Comfortable access via all common web browsers

- Interactive 3D visualization of your customized conveyor system

- Direct contact to our technical service team

Together with you we plan the electrical integration of our conveyor systems into your car wash technology.

- Construction of switch cabinets according to project-specific requirements

- Commissioning and support for system...

Sascha Gellermann (l.)

(Sales and consulting)

+49 5271 9789-11

s.gellermann@minda.com

Henning Sievers (r.)

(Service and spare parts)

+49 5721 9789-41

h.sievers@minda.com