DIRECTLY TO THE TOP - THE SHORT PRODUCTION AND WAREHOUSE LOGISTICS ROUTE

Vertical lifts reliably distribute all sorts of unit goods to various production and warehousing levels. Their unique characteristics frequently make them a better alternative to elevators, forklift trucks and scissor lifts. They don’t occupy much floorspace, are inexpensive and low on maintenance. If discontinuous conveying is possible, they are easy to integrate into existing production and logistics processes.

The fact that they take goods directly to the top means that previously inaccessible spare space can be used, conveyors can be moved to higher levels and new warehousing concepts implemented. At the same time, important traffic and production spaces are not filled and transport routes are shorter.

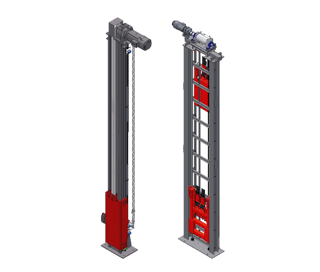

Vertical lifts

MINDA has been making vertical lifts since 2003. Our wide range of conveyor systems for different weight classes is therefore ideal in the real world. Due to their modular design, each and every conveyor is adapted to suit the type of conveying required to perfection.

In the case of particularly bulky goods, significant payloads and challenging dynamics, standard vertical lifts quickly reach their limits. And this is where MINDA comes in. We follow your specifications in order to design and make heavy-duty vertical lifts that integrate perfectly with your production and warehousing logistics.

WHY OUR VERTICAL LIFTS STAND APART

- Superior reliability and service lives

- Efficient and dependable operation

- Exact positioning

- Maintenance-friendly usage

EXCEPTIONAL REQUIREMENTS ARE OUR STRENGTH

CUSTOMISED VERTICAL LIFTS FOR DEMANDING APPLICATIONS

It becomes clear just how beneficial vertical lifts are when they interact with the rest of the machinery. Which is why you’re in good hands at MINDA if your requirements are out of the ordinary. We welcome any challenges you set us, have a keen eye for detail and will provide solutions you can trust. From the moment you make that first decision or select the construction concept, you benefit from our extensive experience with producing special purpose machinery and integrating conveying components.

As a medium-sized company with flat hierarchies, we can offer you a high level of flexibility, on-time delivery and an exclusive contact responsible for your project – from the concept development phase to ready-to-use installation of the product (with control technology integrated too). Experienced staff, excellent technical resources and a high level of vertical integration guarantee high quality production.

Fields of Application

STAND-ALONE?

MINDA vertical lifts don’t have to be connected to the building or other components. In many cases, they can be operated on their own and will therefore also be flexible in the future.

HEAVY DUTY?

It’s not just boards, panels and semi-finished products where weight quickly adds up. MINDA vertical lifts can be designed to cope with loads of over 5 t.

LOTS OF STOREYS?

Goods often have to be moved more than one storey up. Which is why MINDA vertical lifts frequently need to have 20-metre lifting capabilities.

BULKY PRODUCTS TO CONVEY?

Are they especially long, wide (or both)? MINDA vertical conveyors can handle any sizes.

SUPERIOR DYNAMICS?

Even when fully loaded, MINDA vertical lifts achieve a vast number of cycles.

STANDARD RANGE OF VERTICAL LIFTS

MINDA’s standard range of vertical lifts are customised to your requirements and can be supplied with all sorts of different features to nearly all unit goods.

The following aspects can be varied:

- Payload (in fixed increments)

- Effective lift (in fixed increments)

- Lift table size and possibly type of conveying element

Further options are:

- Various safety devices directly on and around the lift

- Automatic locking including buffer storage

- ATEX-compliant design

- Stainless steel type

Ready-to-use installation

The control system can be operated on its own or integrated with existing systems. Visualisation of final positions or configuration is possible.