Apart from lattice boxes, Euro pallets and industrial pallets, more and more disposable or special pallets as well as application- or product-specific load carriers have gained more and more importance on the market.

We manufacture components and complete transport systems for a wide range of pallet types. The basic assembly groups can be combined as required and complemented with various additional equipment. After detailed analyses of the individual application and intensive consultation, we plan the realization of customized applications resp. complex transport systems for you. We can assure you of high-quality production technology combined with a customized software solution and commissioning according to schedule.

Components for palletizing

- Pallet loading station

- Palletizer

- Layer palletizer

- Palletizing robot

- Linear robot/ gantries

- Other additional components

- Pallet magazine

- Pallet alignment

All these components can be combined with our tailor-made conveyor components.As a result, systems optimizing your intralogistics processes are provided.

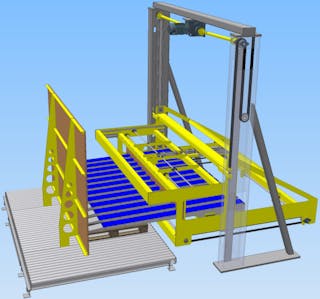

Pallet loading station

The pallet loading station allows positioning an entire stack of products onto a pallet as one unit behind a production area without pallets. The time saving compared to other palletizing solutions is considerable.

The product stack is driven into the station and lifted by a skid unit. At the same time, the alignment walls move together to keep the stack together and to align it.

An empty pallet is fed in crosswise to the infeed direction of the stack. This pallet can, for example, be provided by a MINDA empty pallet robot. After positioning the empty pallet, the stack is lowered onto it.

This type of pallet loading is only used for very compact stacks of any kind. The design meets the customer’s requirements. The pallet loading station can therefore be used for Euro, industrial and special pallets.

Benefits/ Advantages

- Dimensions are adjustable

- For stacking loads up to 4 t and higher

- Precise and careful pallet loading

- Palletizing accuracy ± 15 mm

- Compact design

- Can be combined with empty pallet feeder

- Electric drives

Palletizer

A palletizer is a system of the process automation. Packages are automatically collected on load carriers.

Basically, palletizers are divided into three different designs with respective advantages and disadvantages at MINDA. These are palletizers, palletizing via articulated-arm robots and linear robots (portal palletizer).

Which system is used usually depends on the product types as well as on the creation of the individual layers and the required level of flexibility.

1. Palletizer

In the layer palletizer, for example, a pallet or product layer is assembled by the upstream conveyor technology and then pushed onto the load carrier as a complete layer.

Benefits/ advantages

- Small space requirement

- Precise working method

- Compact design

- Integration into conveyor line is possible

2. Palletizing robot

The option of palletizing goods with an articulated-arm robot is most flexible, as a wide variety of packing patterns can be programmed. The special gripping tools and the respective programming effort also lead to higher costs in the acquisition.

Benefits/ advantages

- Various gripper solutions possible

- High repeat accuracy

- Low cycle times

- Integration into existing systems

- Low maintenance

- For different load capacities

- Low space requirements

Linear robots/ gantries

Linear robots are versatile and provide a high degree of automation. Within the production lines, this technology carries out recurring tasks such as feeding empty pallets or palletizing products. Various processes and product-pallet pairs can be programmed.

MINDA uses linear robots for various tasks and applications. For example, they are used as an automated option for unloading loads on pallets from trolleys or as a protection sheet dispenser within packaging areas.

But linear robots are also used within MINDA systems for various pick and place tasks in production or conveyor lines.

Depending on the application, both the dimensions and the load class can be adjusted. The different versions allow linear movements in X, Y and/or Z as well as the possibility of rotational movement in C. Various gripper solutions complete the gantries.

Benefits/ advantages

- Short cycle times

- High positioning accuracy

- Compact design

- Flexible concept

- Efficient safety system

- Low noise

Useful additional components

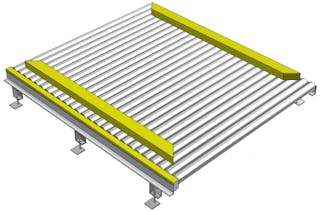

1. Pallet magazine

Pallet magazines are used to stack and destack empty pallets. There are different versions depending on the respective application.

In connection with the appropriate conveyor technology (roller conveyors or chain conveyors), subsequent workplaces can be automatically provided with empty pallets.

Downtimes are eliminated and the palletizing process becomes more efficient.

2. Pallet alignment

Within a conveyor line it may be necessary to align pallets for certain applications. On the one hand, pallets can be aligned centrally to ensure a defined transfer to the following process step.

On the other hand, it is also possible to align a pallet on one side. In this case, the pallet is aligned according to a reference edge.

Further MINDA solutions for building and insulation industry

Our services and fields: